All about electronic pressure switches

Electronic pressure switches have become an important component in industrial automation technology in recent years. They offer numerous advantages over conventional mechanical pressure switches and have the edge in many applications. Here you can find out what an electronic pressure switch is, how they work and what important advantages they offer compared to mechanical pressure switches.

Overview of electronic pressure switches and their applications

Electronic pressure switches are indispensable in today's industry. The sensors can precisely measure and control the pressure in a system. They generate an electronic switching signal when a set switching point is reached. The switching point can be preset at the factory or set via an interface such as IO-Link. It is often also possible to set the switching points directly on the device using the display and buttons.

From the continuous monitoring of hydraulic systems to the control of pumps and compressors - they are used for a wide range of applications. They are also crucial for process control and help machines to function more efficiently.

Advantages of electronic pressure switches in hydraulic and pneumatic systems

The use of electronic pressure switches in hydraulic systems, for example, but also in pneumatic systems, offers a number of advantages over mechanical pressure switches. Unlike a mechanical pressure switch, an electronic one can be adapted precisely to the application-specific requirements. With a mechanical switch, only the switching point can be set. As electronic pressure switches have integrated programmable logic, it is possible to make a wide variety of settings. For example, the switching point and the reset point, the function of the output (hysteresis or window function) and a delay time can be set. In addition, mechanical pressure switches are not suitable for switching low voltages in control systems and modern electronics. As a rule, an electronic pressure switch is always preferred here.

Types of electronic pressure switches

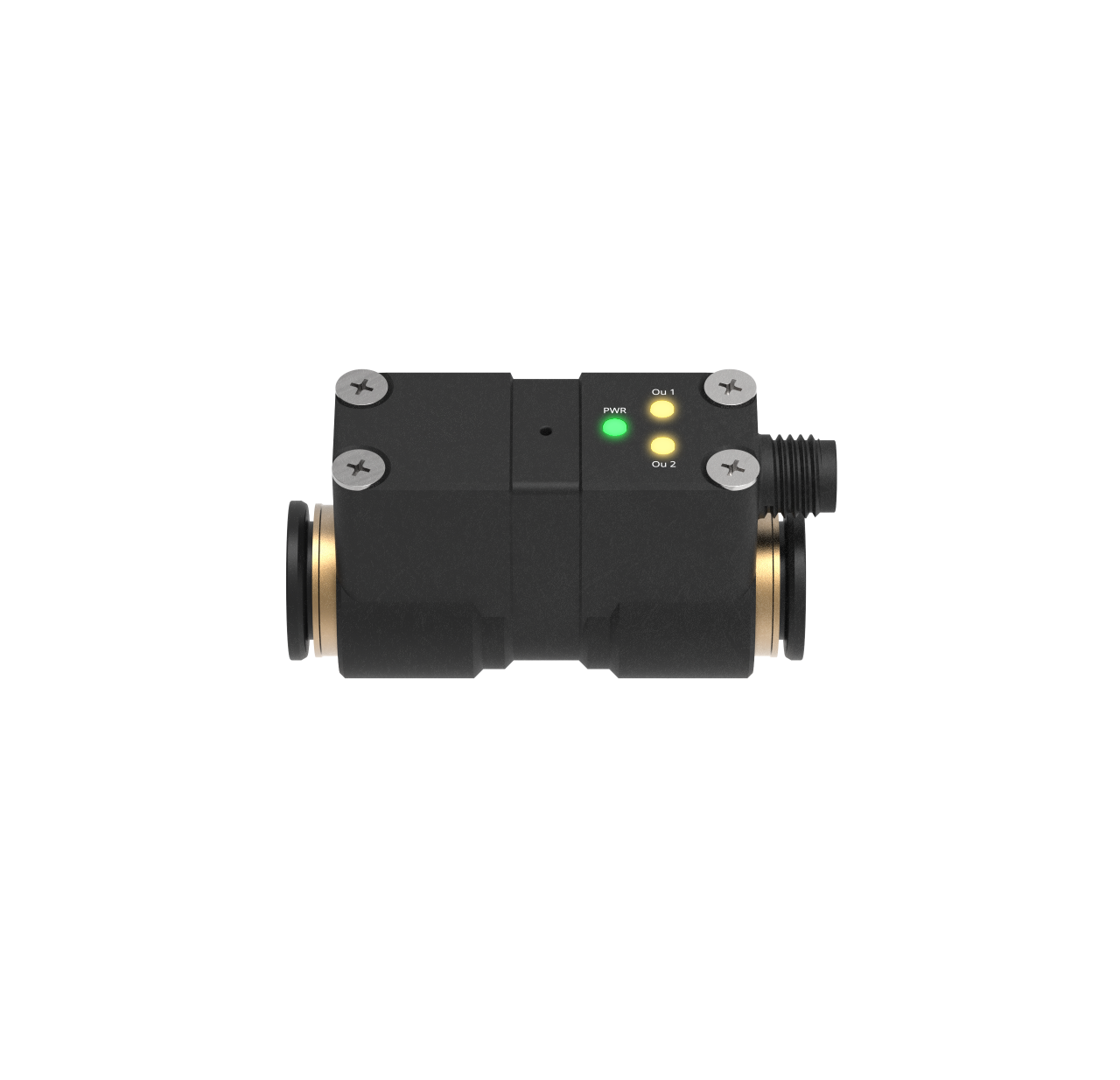

Electronic pressure switches are available in different versions and for different applications. The various types differ in their design and their specific functions. For example, there are switches for use in liquid media, such as water or oil, or for use in gaseous media, such as air. Other distinguishing features include the measuring range of the switch and the electronic connection. Selecting the right pressure switch depends on the specific application and requires careful consideration of the requirements.

- Electronic pressure switches are available in different versions and for different applications.

- The various types of electronic pressure switches differ in their design and specific functions.

- Choosing the right pressure switch depends on the specific application and requires careful consideration of the requirements.

How to choose the right electronic pressure switch for your system

When it comes to choosing the right pressure switch for your system, various factors can play a role. First of all, you should make sure that the pressure switch fits the requirements of your system. To do this, check the pressure range of your system and make sure that the pressure switch covers this measuring range. It is also advisable to pay attention to the accuracy of the sensor. The sensor's connection options should also be suitable for your system. Finally, you should also keep an eye on compatibility with your control system. Choosing an electronic pressure switch that meets your requirements will lead to improved functionality, greater efficiency and therefore cost savings.

Electronic pressure switch

In summary, it is an advantageous, cost-effective and reliable way to control pressure in hydraulic or pneumatic systems. When selecting electronic pressure switches for your system, it is important to consider the type of system and its specific requirements.

This may also be of interest to you:

Dies könnte Sie ebenfalls interessieren:

Häufig gestellte Fragen

Ein elektronischer Druckschalter ist ein Sensor, der zum Beispiel in Hydraulik- und Pneumatiksystemen eingesetzt wird, um den Druck des Mediums zu überwachen und zu regeln. Er ist in der Lage, den Druck innerhalb eines bestimmten Bereichs zu messen und gibt ein Signal aus, wenn der Druck ein bestimmtes Niveau erreicht oder überschreitet.

Er verwendet ein elektrisches Signal, um Informationen über das aktuelle Druckniveau zu liefern, so dass Maschinen optimal gesteuert werden können. Ein großer Vorteil eines elektronischen Druckschalters ist die integrierte programmierbare Logik. Dank dieser kann Sensor auf die verschiedensten anwendungsspezifischen Bedürfnisse angepasst werden.

Elektronische Druckschalter werden in hydraulischen Systemen eingesetzt, um den Druck des Hydrauliköls zu messen und zu regeln. Dies ist wichtig, um die Leistung der Hydrauliksysteme zu optimieren und Beschädigungen an Hydraulikkomponenten zu vermeiden. Oftmals werden mit elektronischen Druckschaltern auch Kühlkreisläufe von Maschinen überwacht. In Pneumatiksystemen werden die Sie verwendet, um den Druck von Druckluft zu messen und zu steuern. Dies ist wichtig, um die Effizienz der Pneumatiksysteme zu verbessern und Fehler zu vermeiden.